Description

Condensers designed specifically for chillers have distinctive features that differentiate them from other types of condensers:

Heavier-gauge piping: Due to the high pressures handled in chiller refrigeration systems (over 300 psi), heavier-gauge piping is required to withstand these conditions without the risk of leaks or ruptures.

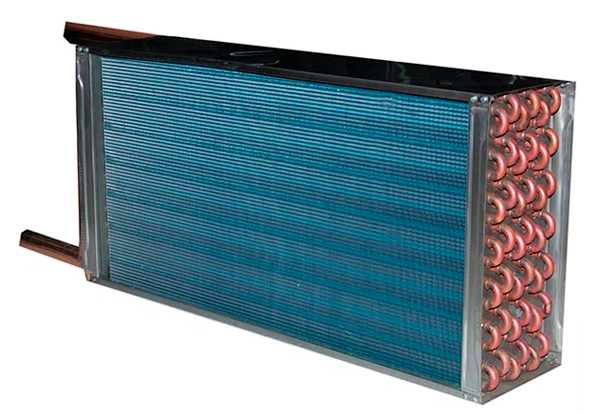

Corrosion-resistant materials: Chiller condensers are made of highly corrosion-resistant materials, such as copper or stainless steel. This is critical to ensuring a long lifespan, as refrigerant and other fluids can be corrosive.

Optimized design for heat transfer: The geometry of the condenser tubes and fins is designed to maximize heat transfer from the refrigerant to the environment. This allows for high energy efficiency.

Wide variety of types: There are different types of chiller condensers, such as evaporative condensers, air-cooled condensers, and water-cooled condensers. The choice of condenser type will depend on factors such as climate, water availability, and energy efficiency requirements.